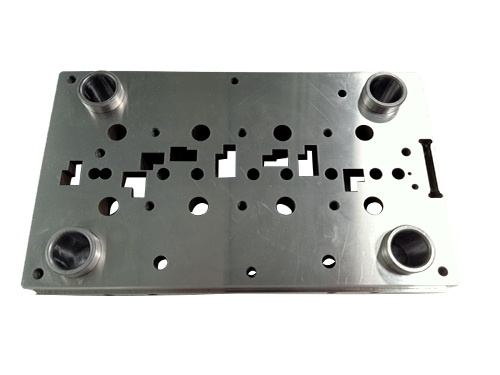

Stamping dies are necessary process equipment in the stamping production process, which play a decisive role in improving product quality, extending product life, and improving production efficiency. However, because the stamping die loses its working size due to frequent wear during the production process, it is difficult to meet the production requirements. Therefore, it is critical to improve the durability (service life) of the stamping die.

Methods to improve the durability of stamping dies generally include the following:

1. Improve the design of stamping die

Whether the stamping die design is reasonable is the basis for improving the durability of the stamping die. Therefore, when designing the stamping die, effective measures should be taken to improve the durability of the stamping die. For example, the life of the small hole punching die is often reflected in the punching die for punching small holes. For this type of stamping die, the length of the small punch should be shortened as much as possible in the design to increase the strength. At the same time, the method of guiding sleeves should be used to strengthen the small punch for protection. In addition, in the design of the stamping die, factors such as the form of the die base, the fixing method and guiding form of the convex and concave die, the determination of the pressure center, and the rigidity of the upper and lower templates should be fully considered. Especially for the blanking die, the selection of the gap value has a great influence on the durability. When designing, the gap of the stamping die should be selected reasonably, and the gap value should not be too small, otherwise it will affect the service life and durability of the stamping die. Practice has proved that, without affecting the quality of the stamping parts, a proper enlargement of the gap can greatly improve the durability of the stamping die, sometimes even several times or tens of times.

2. Correctly choose stamping die materials

Different stamping die materials have different strength, toughness and wear resistance. Under certain conditions, the use of advanced materials can increase durability several times. Therefore, in order to improve the durability of the stamping die, a good material must be selected.

The Toolox series of materials are a new type of pre-hardened tool steel with high toughness, high wear resistance, and basically no internal stress. And it has a very high degree of purity, a very small grain size, and a very high content of S and P. Due to the special composition design, Toolox series materials have very excellent surface treatment performance. Among them, the surface hardness of Toolox44 can reach HRC65 or more after nitriding, and the surface hardness of Toolox40 can reach HRC62 or more. The surface hardness of Toolox33 can reach above HRC58, and the depth is up to 1.8mm.

The above characteristics of Toolox series materials make Toolox series materials have special advantages in some stamping dies.

1) Thicker steel plate (a typical case of 35mm thickness steel plate), stainless steel plate, and non-ferrous metal plate stamping and forming molds, typically air-conditioning fin molds, etc.

2) Stretching die, stainless steel drawing die.

3) Cold extrusion die. Cold extrusion 304 stainless steel, with a thickness of 0.5mm or more, replaces materials such as DC53, and the effect is very good.

4) Large stamping template with high dimensional stability requirements.

3. Reasonably carry out forging and heat treatment of stamping die parts

While selecting high-quality stamping die materials, reasonable forging and heat treatment are required for materials of the same material and different properties, which is one of the main ways to improve the durability of stamping dies. For example, during quenching, if the production is overheated during heating, not only will the workpiece become too brittle, but it will also easily cause deformation and cracking during cooling, which will reduce the durability. Therefore, when manufacturing stamping dies, the heat treatment process must be reasonably mastered.

Toolox material is a quenched and tempered steel directly pre-hardened by the steel plant. No heat treatment is required. With proper surface treatment (such as nitriding), the high toughness of Toolox matrix material and the high hardness of the upper surface layer can achieve excellent Effect.

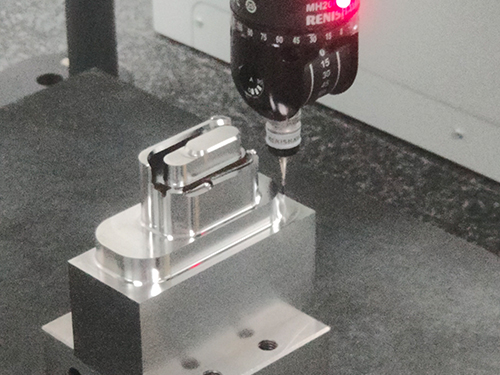

4. Reasonably arrange the stamping die manufacturing process and ensure the processing accuracy

The processing accuracy of the stamping die has a great influence on the durability of the stamping die. For example, due to the uneven assembly gap in the punching die, the die will often be broken under the action of shearing force and affect the life of the punching die. At the same time, the surface finish of the stamping die is too low, which will also reduce the durability of the stamping die. Therefore, during processing, full attention must be paid to the size of the hole spacing, the perpendicularity of the punch to the fixed plate supporting surface during assembly, the uniform spacing of the stamping dies, and the guiding accuracy level of the guide sleeve and the guide post. The higher the manufacturing and assembly accuracy and the higher the surface roughness of the working part, the higher the durability of the stamping die.

5. Choose the correct press

In order to improve the durability of the stamping die, a press with higher precision and higher rigidity should be selected, and the stamping tonnage should be more than 30% greater than the punching force. Normally, the use of a servo punch can increase the life of the mold by more than several tens of times.

6. Reasonable use and maintenance of stamping dies

In order to improve the durability of the stamping die, the operator must use and maintain the stamping die reasonably, and the stamping die should be repaired frequently to prevent the stamping die from working with defects.

The above are several common methods to improve the wear resistance of stamping dies. The significance of improving the wear resistance can not only increase the service life of the stamping die, reduce the production cost of the die enterprise, but also ensure the quality of the products produced and improve the production efficiency.